We know, there’s no such thing as a stupid question. But there are definitely some questions too embarrassing to ask your local shop or riding buddies. AASQ is our bi-weekly series where we get to the bottom of your questions – serious or otherwise.

Question #1: Hi, I’m using a Schwinn stingray. Size is 20 × 4 1/4. Is it same as 4.25? Been looking hard, but I’m yet to find one after my tube burst and I’m looking for a replacement. Thanks! – Vader

Bikerumor: Over the history of the bicycle, as a rule of thumb, tires labeled with fractions are not interchangeable with their equivalent size in decimal form (i.e. 26 x 1 1/2″ does not equal a 26 x 1.5″ tire). Tubes however, are a bit of a different story. Since they’re essentially a round balloon, they’ll stretch to fit within a reasonable size range. In this case though, it doesn’t really matter since the 20 x 4 1/4″ size in both tires and tubes seems to be readily available. They’re sold under the Sunlite brand which should be easy to get from any bike shop with a J&B account.

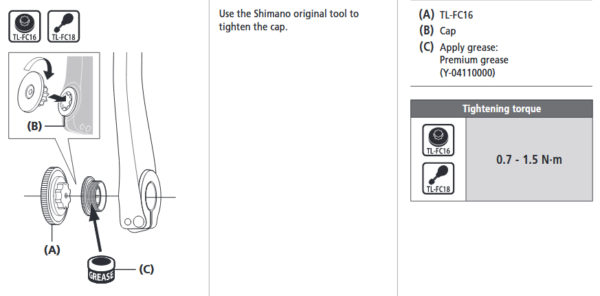

Question #2: What’s the purpose for and how tight should the little plastic crankarm bolt on Shimano cranks for? I usually get it a bit more than finger tight but I’m wondering if that’s too much or not enough? – Ryan

Bikerumor: Officially, that little plastic piece is called the Hollowtech II Left Hand Fixing Cap. Its job is to pull the two halves of the crank together, so that the left crank arm sits in the right place on the spindle and there aren’t any gaps between the arms and the bottom bracket seals. Shimano states that the cap should be torqued to 0.7-1.5 Nm or 6-13 in-lbs. If you’re just using your fingers and not a TL-FC16, TL-FC18, or similar tool, you’re probably not getting it tight enough which could cause premature wear of the BB. However, if you’re saying that you’re using your fingers to turn the TL-FC16 (the little top hat shaped tool) rather than a torque wrench, then you’re probably fine. I typically use the TL-FC18 without a torque wrench and tighten it until I’m sure the crank arms have contacted the BB seals, then back if off a hair since it offers more leverage than the smaller TL-FC16.

Got a question of your own? Click here to use the AASQ form, or find the link under the Contact menu header up top anytime a question pops into your mind!