Getting that perfect saddle can sometimes seem like a chore. Between all of the different brands, widths, and styles, it can be difficult to pinpoint the ideal perch for your bike. The demand for something a little more personal has helped companies like Meld step forward and offer a different take on a solution. They hope to make buying the perfect saddle, when it comes to weight, tech, and above all, comfort, easier by using anatomically personalized constructions.

It’s as simple as logging onto their page, and ordering a mold….

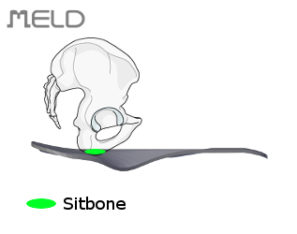

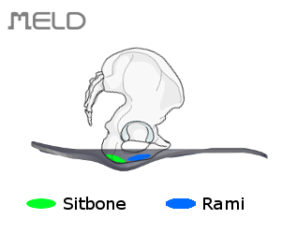

The first step to getting your custom saddle is to order a mold kit from Meld’s webpage. The mold is used to get accurate sitbone spacing and placement. Next, after the mold is sent back for processing, they piece together a general saddle layout that is specifically made for your glutes. Meld assures that the following steps won’t affect the overall comfort, but can be considered for the style of riding you’re planning to do.

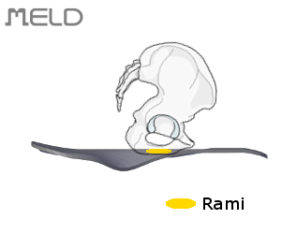

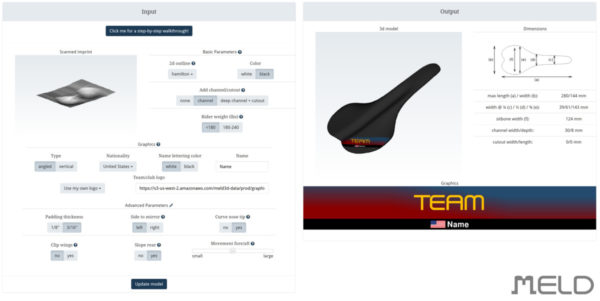

After the bone positions have been mapped, you may choose from a full carbon build or a carbon shell with metal rails. Meld’s carbon shells are said to have some flex where you need it, hopefully providing some extra comfort. Then you’ll input your own needs and wants into the saddle, with options including the outline (general top view shape), which sitbone to mirror (for a symmetrical saddle), a flat or curved nose tip, and a channeled or cutout mid section. There are a few more options that include clipping the wings (side material), slopping the back of the seat, and a bunch of graphic options to make it yours.

Prices: $325 Full Carbon : $250 Carbon and Metal Rails