Advancements in carbon fiber technology have had a profound impact on bicycle frame design. They’re lighter, stronger, stiffer, and in some cases much more compliant. That last one comes as a number of companies look back to the early days of soft tail suspension design, but are doing so in a modern carbon fiber package. Both on the road and on the mountain, the concept of a soft tail frame has hung around for years with some bikes sticking around better than others (the Moots YBB comes to mind). Yet the idea still holds promise – just enough suspension performance to add compliance and aid in handling, all while retaining the sharpness of a hardtail.

While the idea is fairly common, how each company approaches the concept varies greatly from bike to bike. When it came time to redesign their Teamelite 01, BMC used the opportunity to introduce their new Micro Travel Technology or MTT. Promising greater compliance through just 15mm of travel, the Teamelite 01 has a few other new additions as well…

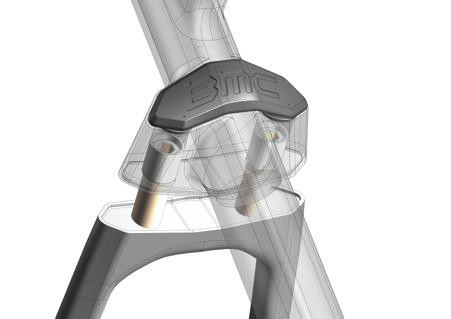

Developed over the past two years with BMC’s Impec Lab in Grenchen, Switzerland, at the heart of MTT is their XCell Damper. Supported by dual guide pins that are accessed through the front of the seatstay and hidden under a molded cap, the damper appears to be a simple elastomer that compresses to allow for 15mm of travel. Available in 3 different damper densities, the frame can be tuned to different rider weights. The design of the damper claims to result in a seat stay that is still stiff laterally and torsionally, but is allowed to compress thanks to the carbon layup of the chainstays and seatstays.

Even with the XCell damper and MTT design, the full carbon frame has a claimed weight of 1,080g with all hardware. BMC points out that the technology allows for racers to base their tire pressures on what will be fastest for the course rather than reducing pressure to add compliance. After all, this is a true race bike for riders like Julien Absalon who are looking to gain seconds wherever possible.

Elsewhere on the frame, the rear end gets upgraded to a 12 x 142mm thru axle rear dropout and a new DTI internal cable routing system adds compatibility for the latest drivetrains including Sideswing front derailleurs and Di2. When not using a front derailleur, a guide plate can be bolted to the FD mount which provides extra insurance against frame damage from dropped chains. Other details include a BB92 Shimano press fit bottom bracket, 1.5-1.125″ tapered headtube, and post mount disc tabs with 160mm max rotor size.

Available in 5 sizes (XS/S/M/L/XL), the XS size adds an additional 85mm of stand over clearance which should make shorter riders happy. Adhering to the BMC Big Wheel Concept, all 5 sizes roll on 29″ wheels. Sold in a frameset for $3,599, the Teamelite 01 will also be offered in the Teamelite 01 XTR Di2 ($10,599), XX1 ($6,599), and XT build for $4,599. Head over to BMC’s site for full specs and geometry info.