If you’ve been following Domahidy Designs on facebook lately, you may have noticed a few teasers popping up. The slow roll has included a few different shots of what appears to be a new mountain bike from Steve Domahidy. As the former co-founder of Niner Bikes, and designer of some noteworthy bikes, Steve has been selling his Domahidy Design bikes for a couple of years now and floated us a teaser along with a few new photos.

You’ll have to tune into Mountain Bike Radio for the full release, but if you read between the lines you can get a pretty good idea of what’s coming…

Since releasing their first production titanium and steel mountain bikes, they’ve released a carbon road bike and now it looks like they’re going completely outside the box and into a… gear box? At first glance, the titanium-looking split chain stay wasn’t a big surprise since they already have that on their other hard-tails, but taking a closer look, something is up with that bottom bracket. After doing a little digging, I found the pic below with the Facebook tagline….

I guess this gives up a lot of info on the new bike, but new boxes came today and I can’t wait to get the final pre-production bike built up! #piniongearbox #notasinglespeed #notelectric #singletrack #mountainbiking @carbondrive

Well, there you have it. It looks like a 12 speed, titanium framed, gearboxed belt-driven hardtail _____ bike. I want to say I see “fat” clearance but I’m not placing any bets just yet. (I’m secretly guessing a plus bike – 27+/29″?). You can catch the official announcement on the Mountain Bike Radio podcast on March 24th. Any other guesses as to what Domahidy is up to?

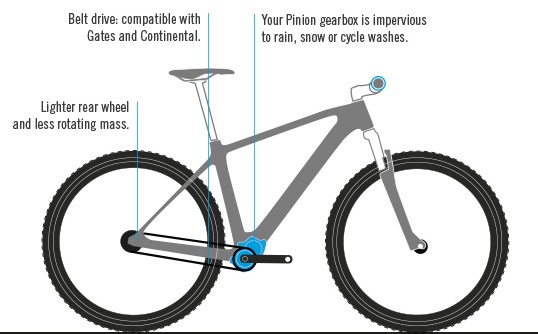

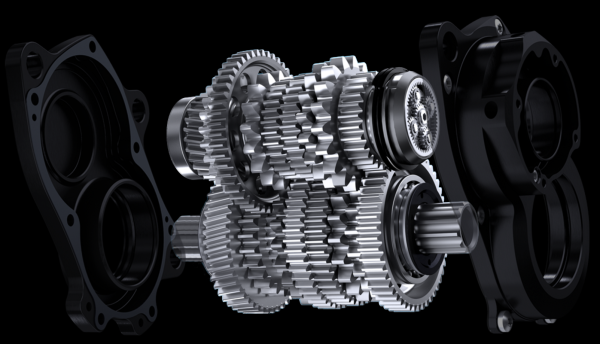

We saw Pinion at Eurobike a couple of years ago that already had an 18-speed gearbox, but they came out with a 9 & 12 speed to reduce weight. Though still significantly heavier than a traditional high-end drivetrain, it takes a lot of weight off of the rear of the bike and puts it in the best place possible which is low and centered.

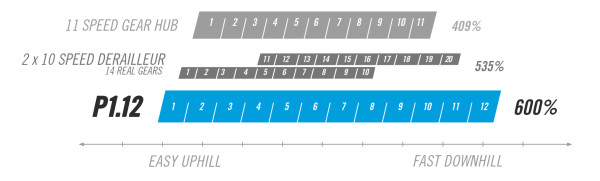

Another benefit is the gear range available on the 12-speed Pinion system verses a 1 X 11 and 2 X 10 is a bit broader (above diagram). Each gear is exactly 17.7% up or down from each other so you’ll always feel a consistent gear difference no matter what gear you’re going to. It’s also virtually a completely sealed system making it perfect for winter slush and you only have to do an oil-change once a year.

From the Pinion Website:

P1.12 HARDFACTS

GEARBOX

| transmission type | Spur gearing |

| Number of gears | 12 |

| Overall ratio | 600 % |

| Gear steps | 17,7% constant |

| Recommended ratio of Rear Sprockets (21t/24t for example) to front |

0,875 |

| Gain ratio in 1st gear (21t/24t)/td> | 1,82 |

| Gain ratio in 12th gear (21t/24t) | 0,3 |

REAL GEARS

Real gears refer to the gear steps of a bicycle transmission that can be optimally used. In derailleur gears, the skewed running of the chain leads to significant losses of efficiency. In addition, when there are two or three front sprockets there will be redundant, i.e. equivalent, gears. A 3×10 derailleur transmission, for example, actually only offers 14 or 15 real gears from this perspective.

TECHNICAL DETAILS

| Chain line with Pinion chain ring | 54 mm |

| Maximum input torque | 250 Nm |

| Axle standard | Pinion splined shaft |

| Q-faktor 1 | 174 mm |

| Lubrication | Splash lubrication |

| Oil type | Pinion gearbox oil 2 |

| Oil capacity | 60 ml (2.0 oz) |

| Temperature range | 5 °F to 104 °F |