Since June, Nick Crumpton has been producing his own bladder molded carbon fiber frame tubes in house in Austin, TX.

Why? This gives them self reliance, and it gives them a “net shape” on the outside, meaning the outside diameter and shape is always perfect, all of the butting and tapering can be done on the inside. That’s versus rolled tube construction where layers are wrapped over a metal tube and have a fixed interior size but variable external diameter and thickness.

Crumpton says it also means all of the carbon is functional. In other words, it doesn’t need any superficial cosmetic layers that could add weight…

Lastly, it lets them ovalize the tubes to take full advantage of the junctions. Basically, Crumpton says it gives them complete control over the finished product while making it look better and saving a few grams.

Like last year, he’s holding off for a bit before offering disc brakes for road bikes until it all shakes out more. Nick says they’re small enough that the limited demand doesn’t justify the expense of new molds and testing. Yet, anyway.

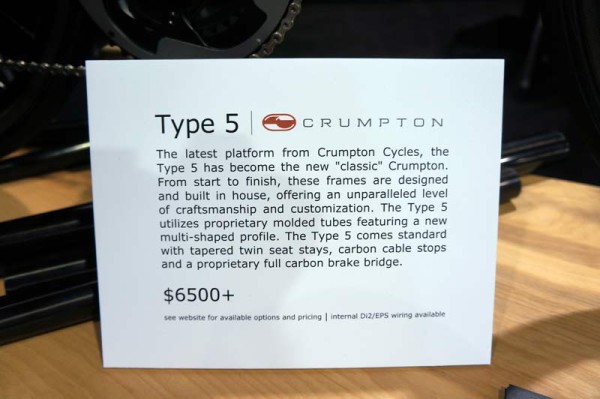

The new tubes come together to create the new Type 5 road frame, his current top of the line model.

The Type 5 shown on left versus his previous standard models using third party tubes. Note the smoother transition between tubes now that he can match the tube diameter and width to the head tube perfectly.